Fabricamos y adaptamos cualquier cabezal del mercado

Aportamos mejoras en productividad, procesos de trabajo y costes finales.

Tecnología, innovación y experiencia en todo el mundo.

Para poder adaptarnos a las necesidades más específicas de nuestros clientes, fabricamos cabezales especiales, adaptados a sus necesidades. La gran cantidad de cabezales fabricados en MYL durante todos estos 45 años nos permiten tener una aplica gama de modelos, adaptables a las necesidades del cliente de manera ágil. Gracias a los últimos medios de producción, a la incorporación de tecnologías de última generación y al uso de ingeniería propia estamos preparados para la fabricación de cualquier modelo de cabezal. Y para ello, y en base a la necesidad de cubrir dichas exigencias, hemos desarrollado un software especialmente creado para MYL, capaz de responder a los procesos de manera única y personal.

ID Grinding

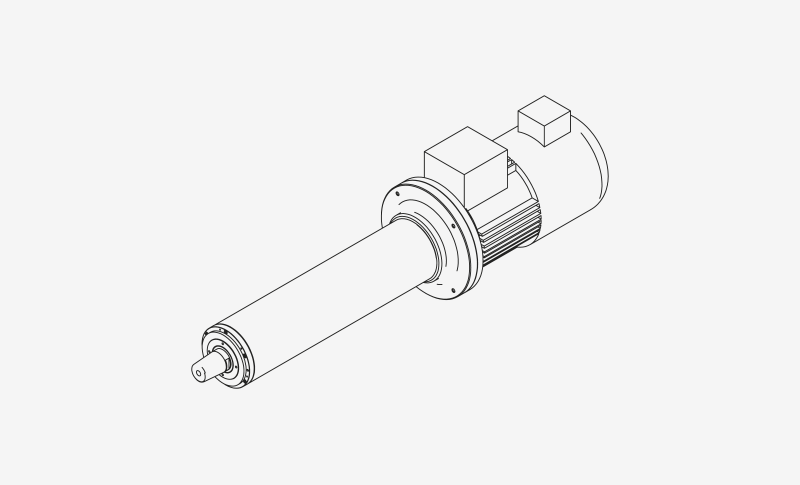

Mechanical transmission: Belt driven spindles for grinding internal diameters. Grinding from 2 mm diameter and lengths of up to 2000 mm. Air-oil or permanent grease lubrication.

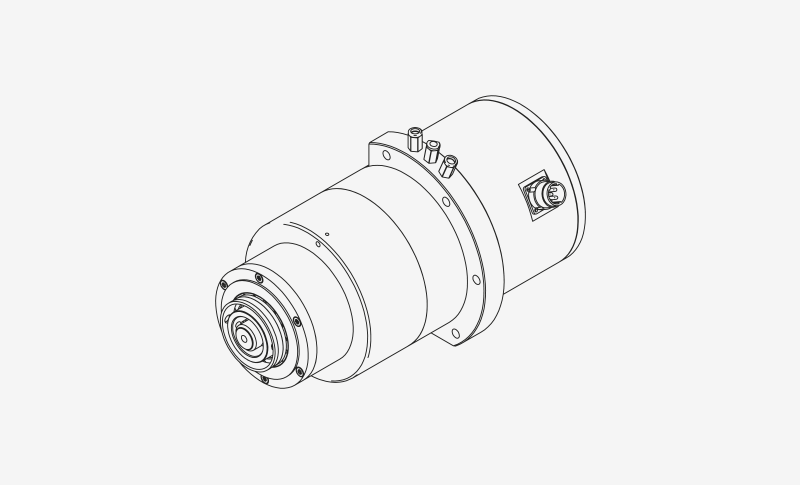

Motor transmission: High frequency motor driven spindles for grinding internal diameters. Synchronous and asynchronous integrated motors. Water or forced ventilation and cooling. Powers from 0.75 kW and working speeds of up to 120,000 rpm. Can be supplied with air-oil lubrication unit and frequency inverter.

OD Grinding

Mechanical transmission: Belt driven spindles for grinding external diameters. Incorporation of a radial force compensation system to prevent pulling of the belt. Options to add dynamic wheel balancing systems.

Motor transmission: High frequency motor driven spindles for grinding external diameters. Synchronous and asynchronous integrated motors. Water or forced ventilation cooling. Powers from 0.75 kW to 100 kW. Can be supplied with lubrication unit and frequency inverter. Automatic wheel change and dynamic balancing systems option.

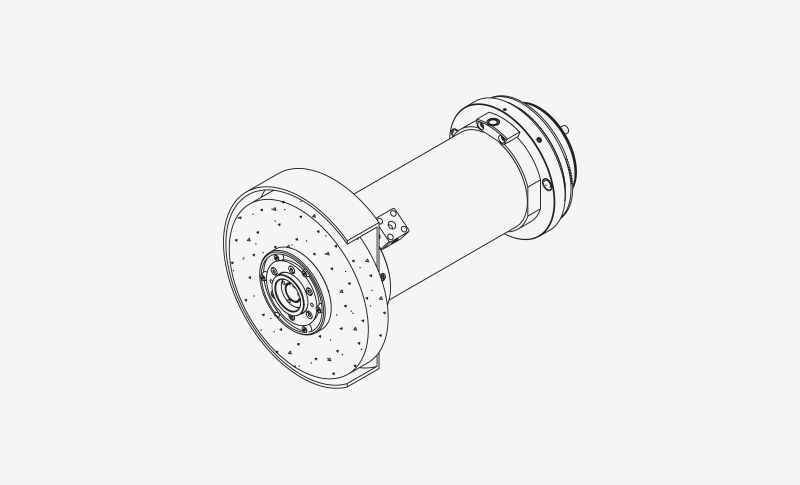

Hydrostatic external grinding

Mechanical transmission: Belt driven hydrostatic spindles for grinding internal diameters. Special pulleys with belt pull radial force compensation system. Bodies with clamps, wheel couplings and oil connectors in accordance with customer requirements. Can be supplied together with the hydraulic unit.

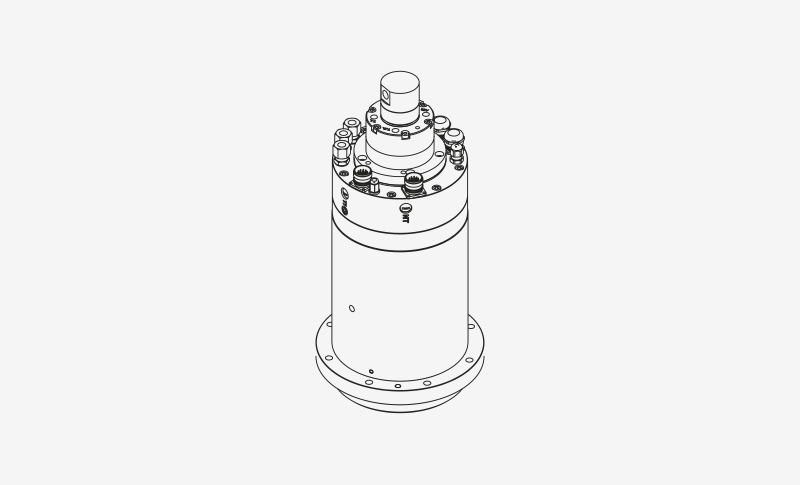

Motor transmission: High frequency motor driven hydrostatic spindles for grinding external diameters. Max 6000 rpm for grinding with CBN grinding wheels. Dynamic balancing systems. Bodies with clamps, wheel couplings and oil connectors in accordance with customer requirements.

Customized

Special spindles according to customer needs. Drive spindle for grinding. Grinding electro-spindle for gantry milling machine. External grinding units for rubber and polyurethane. Grinding spindles for vertical lathes with automatic spindle changing. External and internal grinding units for horizontal lathes. Wheel diamond dressers. Internal grinding units adapted to a CNC turning machine. Applications for frighten welding.

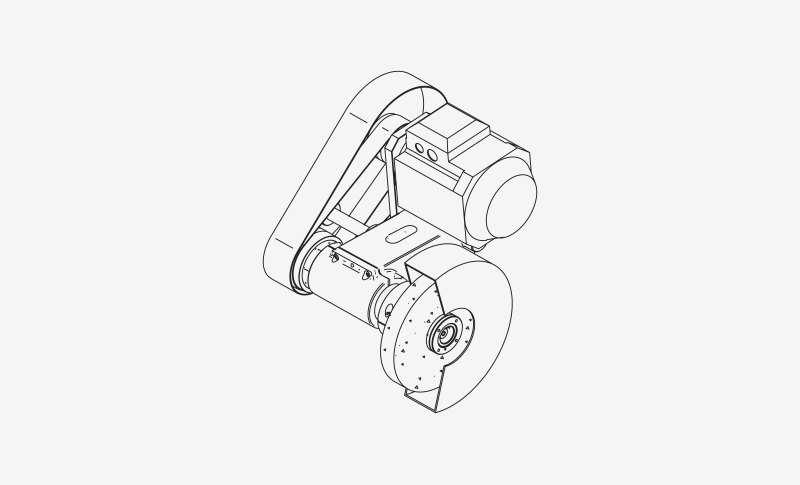

Tool post grinders

The MYL tool post grinders equipped with the renowned MYL grinding spindles are regularly used on lathes for external and internal grinding and front faces, as well as on planing machines and others.

Milling

Belt or direct motor driven milling spindles. ER, SK, HSK and special clamping systems. Grease and air-oil lubrication. Option to install accelerometers and temperature sensors for the bearings.